What’s Keeping the Water in the Pool? A Scientific Approach to Waterproofing

When it comes to swimming pools, waterproofing is often assumed, not engineered. Builders focus on structure. Designers focus on aesthetics. Homeowners focus on features. But few ask the most fundamental question: What’s keeping the water in the pool?

Historically, pool builders have relied on concrete, tile, plaster, or thin coatings to do the job of waterproofing. These materials may resist water for a time, but they are not designed to provide true, long-term waterproofing. True watertight materials such as PVC (polyvinyl chloride), offer a proven waterproofing solution for pool builders.

Polyvinyl chloride, commonly known as PVC, is a widely used synthetic plastic polymer. It is versatile, durable, and relatively inexpensive, making it a popular choice for various applications, especially in construction. PVC can be found in both rigid and flexible forms, depending on the addition of plasticizers. The PVC used for waterproofing swimming pools is made flexible by the use of plasticizers. PVC is known for its smooth, non-porous surface that is resistant to water, chemicals as well as UV radiation. The use of PVC is therefore ideal for outdoor construction, plumbing and waterproofing membranes.

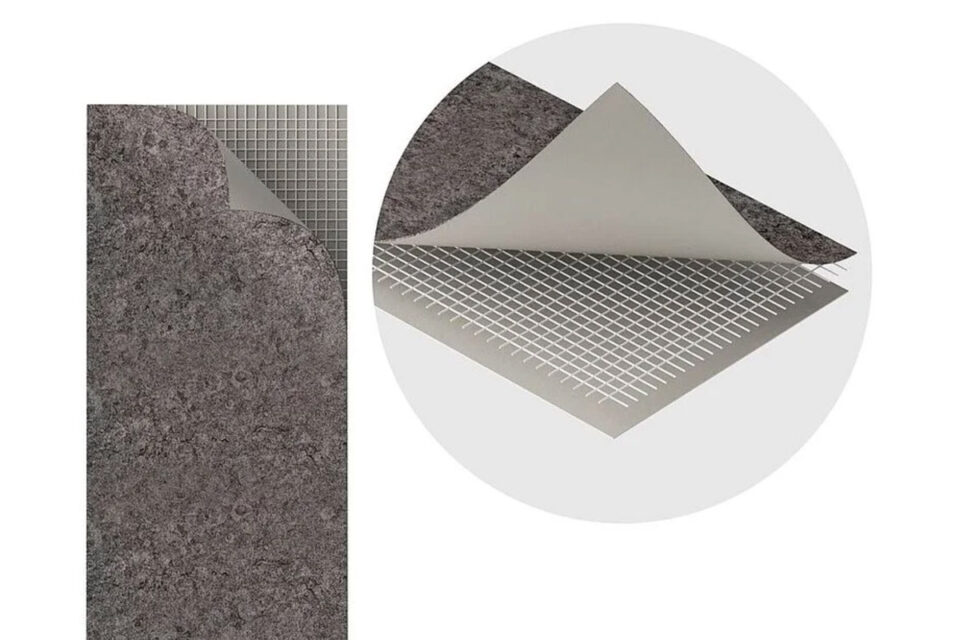

PVC liners and reinforced PVC membranes are the two main products made of PVC commonly used for swimming pool waterproofing. PVC liners are flexible sheets that provide a smooth, watertight surface ideal for residential pools due to their ease of installation and cost-effectiveness. Reinforced PVC membranes, on the other hand, consist of two sheets of vinyl that are laminated with a core of a polyester mesh to provide greater strength, durability and resistance to tearing without losing the elasticity and flexibility needed to accommodate different pool shapes, steps, tanning ledges, vanishing edge and beach entry pool designs etc. As a result, reinforced PVC membranes are ideal for high-end, larger commercial pools as well as residential pool construction and waterproofing.

Often misunderstood or lumped together with traditional, flexible vinyl liners, reinforced PVC membranes are an entirely different class of product that provides a true waterproofing solution and other benefits that meet the demands of performance and aesthetics required for building and renovating swimming pools.

Understanding the Difference: Reinforced PVC Membranes vs. Liners

It’s important to take the time to understand the differences between a reinforced PVC membrane versus a traditional, vinyl pool liner. While both use vinyl as a base material, the comparison between a reinforced PVC membrane and a vinyl liner is like comparing architectural-grade materials to decorative coverings — similar in base composition, however they are designed for very different applications and performance demands.

Traditional vinyl liners are made of a thinner, unsupported PVC sheet that are prefabricated to the pool shape and vacuum-formed into place. They are cost-effective and are best known for use in residential applications, especially in North America. On the other hand, reinforced PVC membranes are multi-layered systems with an internal polyester mesh, installed by certified technicians. They are welded onsite to create a seamless, robust lining with decades of durability. This product is commonly used in residential pools in Europe where it is the preferred solution for residential pool construction and waterproofing. Because of their strength, reinforced PVC membranes are frequently specified by architects and engineers for commercial pool applications, especially when waterproofing is of the utmost importance such as in elevated pools or pools with high bather loads.

The Physics of True Waterproofing

To determine the most effective pool waterproofing system, we must look at the physics of how water interacts with different materials:

- Permeability: Concrete and rigid coatings are porous by nature. Over time, water will migrate through capillaries, especially under pressure.

- Vapor Transmission: Even small amounts of vapor transmission can cause long-term damage behind finishes, such as blistering.

- Structural Movement: Pools are dynamic structures. Ground settling, temperature expansion, and water pressure cause constant micro-movement of the pool structure.

- UV and Chemical Degradation: Exposure to sunlight and pool chemicals breaks down many traditional finishes over time, compromising waterproofing integrity.

Only non-porous, flexible, and structurally independent membranes provide full waterproofing protection. Reinforced PVC membranes meet all the criteria:

- Zero permeability to liquid and vapor

- Resistance to hydrostatic and osmotic pressure

- Crack-bridging flexibility

- UV, chemical, and abrasion resistance

- No reliance on adhesives or substrate bonding

Making the Smart Choice: A Physics-Based Evaluation

Both builders and consumers should take the time to evaluate waterproofing systems for their swimming pool by asking themselves these physics-based questions:

- Is the system truly impermeable?

- Can it tolerate movement, vibration, and seasonal changes?

- Does it resist chemical and UV degradation, as well as freezing conditions?

- Can it be repaired or inspected after installation?

- Does it function independently of the concrete structure?

Reinforced PVC membranes check all the boxes — and they are backed by decades of proven use in the most demanding pool environments—from Olympic venues, hotels, resorts, water parks, high-rise elevated pools and elite residential properties.

Freeze-Thaw Resilience: A Hidden Advantage

In colder climates, swimming pools face a powerful natural stress: the freeze-thaw cycle. Water seeps into small cracks, freezes, expands, and worsens structural damage over time. Rigid coatings — including tile, plaster, or epoxy — cannot flex with this movement and often fail seasonally. Unlike other materials, reinforced PVC membranes are immune to this destructive freeze-thaw process. Their flexibility and mechanical independence from the concrete shell allow them to absorb expansion and contraction without cracking, delaminating, or weakening. This makes them ideal for pools in seasonal climates where winterization is a necessity.

Built to Move, Designed to Last

Swimming pools are not static. They expand and contract with temperature, vibrate with use, and shift subtly over time. Most finishes can’t keep up — but reinforced PVC can because they:

- Are mechanically anchored to the shell — not bonded with adhesives that can fail

- Bridge cracks and joints, maintaining water tightness

Additionally, reinforced PVC membranes are soft underfoot for swimmers, with optional textures for safety and aesthetics. They are also easily repairable, without the need for costly resurfacing.

It is therefore no surprise that reinforced PVC membranes are becoming the go-to specification for new construction, renovations, and commercial aquatic centers worldwide, especially since the product is offered in 60,70 & 80mil thicknesses.

Waterproofing Is Not a Finish — It’s a Foundation

Reinforced PVC membranes are not just beautiful — they are engineered systems that deliver waterproofing as a scientific certainty, not a best guess. While other materials try to decorate or seal over a porous shell, membranes become the barrier, offering decades of reliability, even in harsh or variable environments. In today’s construction landscape, performance matters. And the physics points in one direction: reinforced PVC is the future of pool waterproofing.

In addition to the structural solution provided by these membranes, reinforced PVC membranes are now available in a wide range of new natural stone colors and textures that make them attractive to architects, designers and consumers. In fact, when builders and consumers see the variety of finishes available in reinforced PVC membranes, they are immediately drawn to the way they enhance and blend beautifully with today’s popular decking and coping treatments.

With these new stone and marble patterns, colors, and finishes, more and more hotels, athletic facilities, and wellness spas are choosing reinforced PVC membranes because they want a more attractive look that enhances the architectural design of the facility. The RENOLIT TOUCH Vanity white marble product, for example, looks amazing for large commercial spas and soaking tubs used in wellness centres, health spas, athletic facilities, and hotels.

Final Word: Waterproof First, Then Design

Waterproofing should never be an afterthought. It should be the first technical layer of decision-making, not something hidden behind tile or assumed to come with plaster.

Reinforced PVC membranes are not just a finish — they are a complete, engineered waterproofing solution. For consumers who value longevity, and for professionals who stake their reputation on reliable construction, these membranes offer a proven, physics-based path to performance and peace of mind.