Safe Water Simplified

Aquasol’s Advanced Universal Interlock

Whether it’s a community pool, waterpark or resort feature, keeping water in perfect condition is a full-time job.

Houston-based Aquasol is helping pool professionals meet the challenge with automated controllers that continuously monitor pH and sanitizer levels — eliminating guesswork and reducing the risk of human error. These controllers are key to Poolsure, Aquasol’s water management arm, which serves around 7,500-8,000 commercial pools across the Gulf Coast.

Kevin Boyer, chief operations officer of Aquasol, explains that the company has been closely following updates to the Model Aquatic Health Code, which emphasizes multilayered safety interlocks, frequent challenge testing and logging. Though not mandated by law, these best-practice guidelines are essential for public aquatic facilities.

A safety upgrade

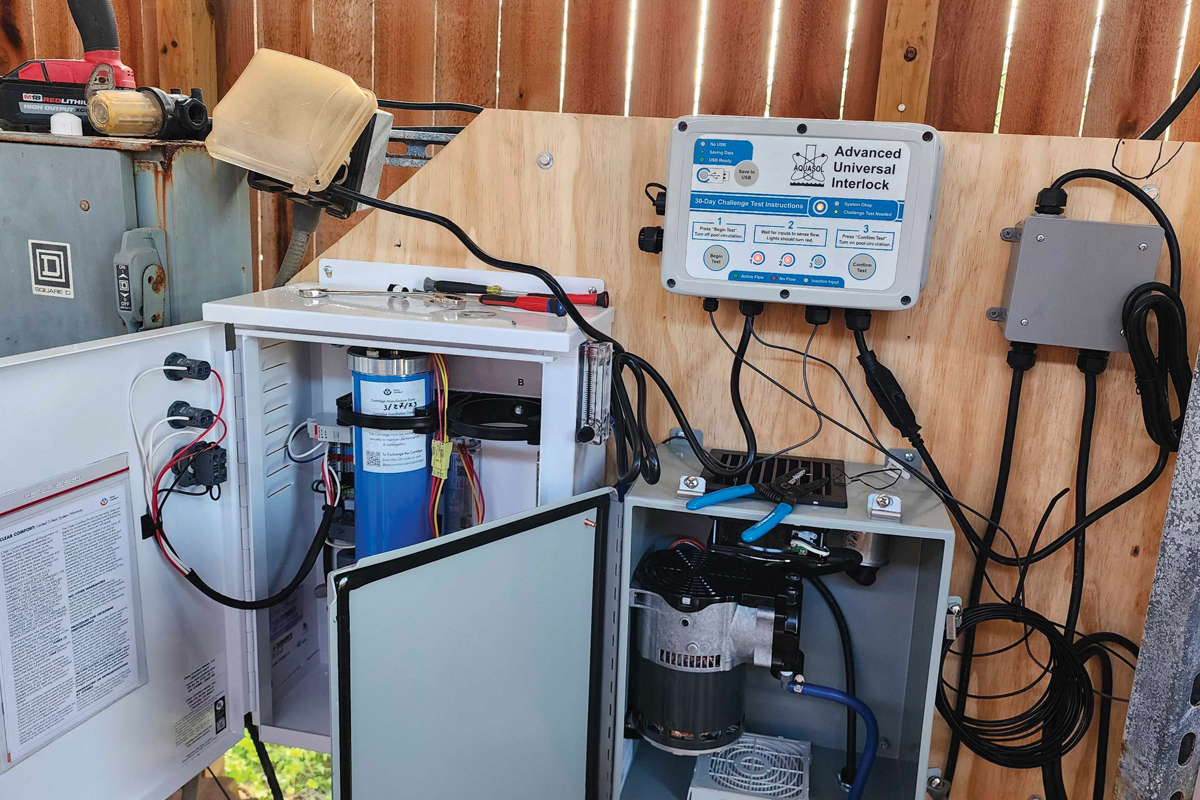

In response to the MAHC, the company developed the Advanced Universal Interlock, a multilayer electrical interlock system that immediately disables chemical feeders when low or no flow is detected in the pool systems. The AUI helps prevent injuries to swimmers caused by unintended chlorine gas creation and exposure. It also features built-in alerts, challenge testing and logging capabilities — all designed to meet MAHC standards.

Newly launched, the product is “easy to install and can retrofit MAHC standards on any pool with any existing feed system with any common safety switches as inputs,” Boyer says.

Installation is simple, adds Brian Zielinski, senior business development manager for Poolsure, “You just plug it in.”

Development challenges and successes

The development process, however, wasn’t so easy.

“We started the development in January 2020, which is probably the worst possible time that we could have decided to start building an electronic device — but we did, not knowing what was coming,” Boyer says, recalling the pandemic-era chip shortage.

They realized quickly that, while it was easy to build a new pool with multiple interlocks designed from the beginning, it was more difficult to retrofit the different types of chemical feed systems, but they persisted.

The AUI operates by sitting between the pool’s interlock sensors and the chemical feed pumps. It has up to three switched device inputs that monitor flow, sending output signals to the controller or shutting down the chemical pumps if a flow interruption is detected. Additionally, the AUI prompts a 30-day challenge test to verify that all switches are working correctly, with logs for ongoing monitoring.

“It is a simple test, but each one of these interlock devices can fail — they’re switches in most cases,” Boyer says. “So the challenge test is there to make sure that switches are operating correctly.”

Zielinski emphasizes the importance of the challenge test. In addition to daily checks, the 30-day test is mandatory.

“It resets the AUI,” he says. “You have to do it, or the AUI will stop working and shut down all the systems, which protects the operator across the board.”

Aquasol AUI: Ready for the market

Bringing the AUI to market turned out to be a four-year process because of the design retrofit process, chip shortage and lengthy approval process.

“We wanted to get it certified by UL and the Council for the MAHC, which it now is,” Zielinski says. Production began in early 2024, beta testing is complete and the AUI is now available for Poolsure customers and the rest of the commercial pool industry.

While other interlock systems exist, Boyer says the AUI is unique in its combination of input/output flexibility and built-in challenge testing.

Aquasol plans to incorporate these capabilities into future versions of its chemical controllers and hopes other manufacturers will follow suit to improve pool safety industrywide.